2024 Mustang Mach-E Replaces Original Rear Motor With F-150 In-House Unit

Sandy Munro criticized the original Mach-E rear motor as being needlessly complex.

At a Glance

- Lighter

- Simpler

- Torquier

The original 2021 Ford Mustang Mach-E employed drive modules from different suppliers for its front and rear axle drive systems, with one module earning accolades for its simplicity and the other being criticized for its complexity.

When technical analyst Sandy Munro tore down a Mach-E, he was effusive in his praise for the front drive unit, but he was not impressed by the complicated solution for the rear drive unit.

Both drive unit assemblies were provided by BorgWarner and they both integrated LG-supplied electric motors, according to BorgWarner. "BorgWarner was asked to launch the program in a very short period of time, which we did flawlessly and with no quality issues," said the company in a statement. "Ford did not give BorgWarner an opportunity to produce our own motor, but rather asked us to integrate a competitor’s motor."

Ford took note of Munro's criticism while also fielding customer requests for faster acceleration from the vehicle that is flying the Mustang banner into the electric age, explained Mustang Mach-E chief engineer Donna Dickson in a talk with Design News.

Following the Mach-E’s launch, Ford sought the opinions of its customers to press a fast program of improvements that could be made in the first three years, said Dickson. One portion of that effort has been the addition of the Always On service in 2023 that lets drivers send recorded voice comments to the engineering team right from their car.

What they heard was that while the Mach-E was quick, it wasn’t quick enough to properly defend the honor of the Mustang badge it wears. “We heard, “We want better performance. And we definitely want a better quarter-mile time.” The new model shaves 0.6 seconds off the quarter-mile time, achieving 11.8 seconds in top-of-the-line GT Performance Upgrade trim.

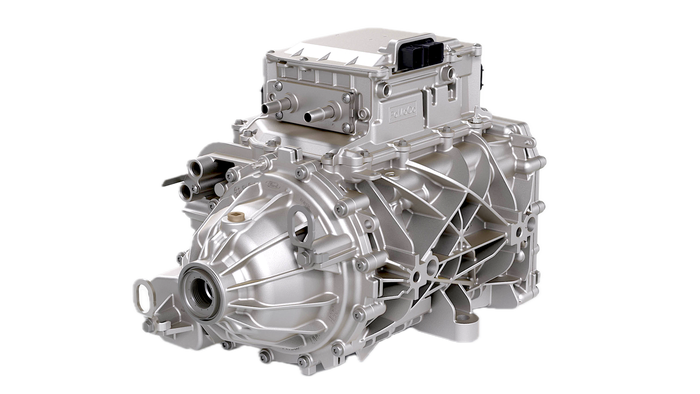

Ford's in-house eMotor, as used in the F-150 Lightning. FORD

One way to accomplish that would be to substitute Ford’s own in-house electric motor used by the F-150 Lightning for the BorgWarner-supplied rear motor. The Lightning’s motor is lighter and makes more torque (387 lb.-ft vs. 317 lb.-ft.), giving customers the performance they sought. This whittles 0-60 acceleration to 5.6 seconds for the base rear-motor-only model, compared to 5.8 seconds before.

Replacing the rear drive unit would address Munro’s criticisms. Also, by increasing the production volume of the in-house motor, Ford could improve the economies of scale of the purchased components it uses to build the motors, reducing costs, Dickson explained. “We knew it was going to be a better decision for us,” she said.

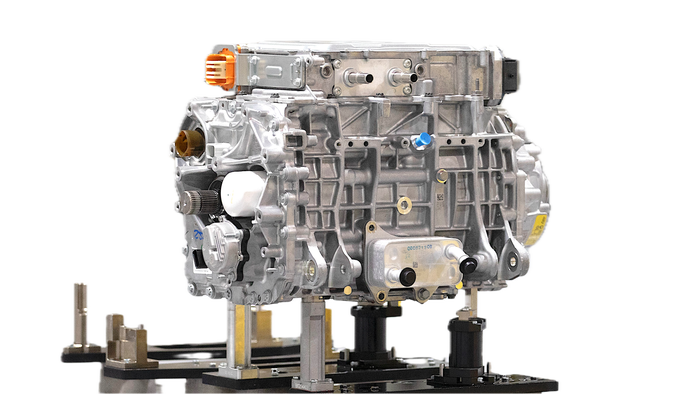

The original rear drive unit used in 2021-'23 Mustang Mach-Es. BORGWARNER

A better decision, but not a simple one. That’s because the Ford eMotor is shaped differently than the motor used originally in the Mach-E. The Ford motor could fit, but not well. That’s because the mounting points are different and its shape interfered with fasteners for other important parts like the rear suspension toe links and lower control arms.

“It was pretty difficult, putting it in after we launched,” Dickson recalled. “It is a different shape and fitting it into our package with the subframe was difficult.”

Engineers from a variety of areas huddled to address the issue. “We spent a month with a cross-functional team to fit it in during a month of workshops identifying what we could do, 3D printing parts to mock up the fit,” she said. “From there it was only a 16-month development program.”

The team knew it was possible to fit the 1T50L variant of the Lightning’s motor into the Mach-E because the company was already using another version, the 1T40L in Chinese-market Mach-Es, said Dickson. The difference is that the U.S. factory is expected to run at a fast pace using automation, while the Chinese plant can run more slowly using more manual labor that can cope with challenging access to fasteners.

“They didn’t have a lot of jobs per hour so they could put resources on it to fit it in,” Dickson said. “We wanted to stay with automation and not have it be manual in the plant.” As it has turned out, using the Ford motor is still a bit of a manufacturing headache, but not so much as to constrain production speed, she said. Dealer service technicians will be happy to know that the change makes no difference to the serviceability of the vehicle.

The Ford motor is an oil-cooled permanent magnet synchronous segment coil-wound motor, while the original motor employed hairpin windings like we’ve seen in Rivian’s electric motor. The motor is oil-cooled with coolant from the outside passing through the inverter to a heat exchanger that cools the oil used inside the housing.

Munro’s high estimation of the BorgWarner front drive unit design could be an indication of Ford’s satisfaction with that drive unit because Dickson said the company has no plans to replace the Mach-E’s front modules with in-house units.

About the Author(s)

You May Also Like